The manufacturing process begins by transposing the drawing to a matrix of copper, iron, tin or steel, whose function is to separate the colors of the mosaic picture. The matrix is molded, welded and placed inside a metal box.

A paste of cement, sand, marble dust, water and metal oxides to pigment Is prepared in metal buckets. Each bucket has a different color preparation.

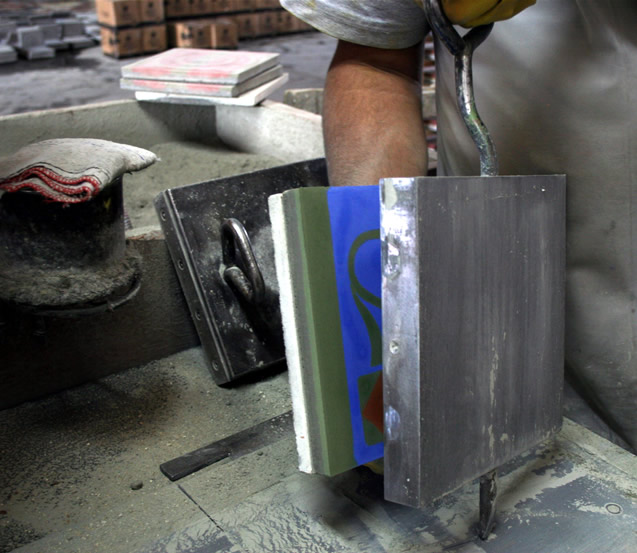

These preparations are placed simultaneously in the matrix, each in its corresponding compartment. The matrix is adjusted to avoid drips of pigment between compartments, and removed carefully.

The secret of the product is the density of each pigment preparation. There are cases where the designs are required that the color preparation is poured drop by drop.

This first layer, which forms the finishing top layer is sprinkled with a mixture of dry sand and gray cement, which gives a higher hardness.

Next is placed a base layer consisting of a cement mortar, sand and water.

In this phase the tile is pressed. The press operation is made all at once, and allows excess water pass from the decorative layer to the base layer. After the pressing the mold is removed carefully and the mosaic is checked manually.

The tile is then submerged in water for at least 8 hours, giving the «curing of the mortar», this is, through a chemical hydration reaction the cement hardens and solidifies. This chemical reaction through water is the reason of the name hydraulic tile.

The last stage of this production process is the drying of the tiles. After being removed from the water, the tiles are stored in a dry place for a month to complete crystallization of the cement. And finally they are ready for use.